Angular Contact Ball Bearing 7021AC For Crusher Vibrating Screen

Keywords:

Category:

Angular Contact Ball Bearings

Product Details

Angular Contact Ball Bearings:

Angular contact ball bearings can bear radial load and axial load at the same time.Able to work at high speed.The higher the contact Angle, the higher the axial bearing capacity.The contact Angle is the Angle between the contact line of the ball and raceway in the radial plane and the vertical line of the bearing axis.High precision and high speed bearings are usually 15 degrees of contact.The contact Angle will increase under axial force.

Cage material:

steel plate, brass or engineering plastic, molding methods are stamping or turning, depending on the bearing form or use conditions.

Main applications of angular contact ball bearing:

Papermaking machinery, reducer, railway vehicle axle, rolling mill gearbox bearing seat, rolling mill roller, crusher,vibrating screen, printing machinery, woodworking machinery, all kinds of industrial reducer, vertical self-aligning bearing with seat,elevator wheel.

Structure form:

1. Separation type angular contact ball bearing

This bearing code is S70000, its outer ring roller side has no lock, can be separated from the inner ring, cage, ball assembly, so can be installed separately. This kind of micro bearing with inner diameter less than 10mm is used for gyro rotor, micro motor and other devices that have higher requirements for dynamic balance, noise, vibration and stability.

2. Non-separated angular contact ball bearings

The ring groove of this kind of bearing has a lock, so the two rings can not be separated. It can be divided into three types according to the contact Angle:

① Contact Angle α=40°, suitable for bearing large axial load;

② Contact Angle α=25°, mostly used for precision spindle bearings;

③ Contact Angle α=15°, mostly used for large size precision bearings.

3. Configure angular contact ball bearings in pairs

Angular contact ball bearings configured in pairs are used for bearing both radial load and axial load, and can also bear pure radial load and axial load in any direction. This kind of bearing is provided to the user by the manufacturer according to certain pre-load requirements. When the bearing is installed on the machine, the clearance in the bearing is completely eliminated, and the ring and the ball are in a pre-tightening state, thus improving the steel of the combination bearing.

Factory Appearance

The company was founded in 1998,covers an area of more than 90,000 square meters, plant area of more than 20,000 square meters, more than 200 employees, more than 20 technical engineers, has passed the international ISO9001:2008, ISO/ TS16949:2009 and other quality management system certification

Packing and shipping

For users to designdevelop, trial-produce all kinds of special purpose bearings, and do our best to provide high-end customers around theworld with the best solutions and good after-sales service!

Customer Visit

The company has many years of experience in the industrial field of bearing supporting and industrial service, the products are exported to the United States, Germany, Italy, France, the Czech Republic, Russia and other European and American countries and supporting enterprises, the company both at home and abroad enjoy a good business reputation!

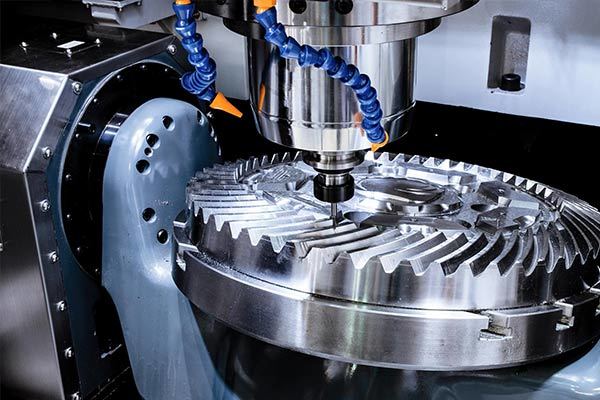

Application

Bearings are widely used in various industries for their excellent performance and reliability. They play a crucial role in ensuring smooth and efficient operations of various machinery and equipment.

RELATED PRODUCTS

MESSAGE