LM50UU Linear Bearing

Keywords:

Category:

Linear Blocks&Rails

Product Details

Features:

Linear bearings are used in conjunction with quenched linear drive shafts. A system of infinite linear motion. Because the load ball and quenched transmission shaft are point contact, the allowable load is small, but in linear motion, the friction resistance is minimum, the precision is high, and the movement is fast.

Application:

Linear bearings are more and more widely used in electronic equipment, food machinery, packaging machinery, medical machinery, printing machinery, textile machinery, machinery, instruments, robots, tool machinery, CNC machine tools, automobiles and digital three-dimensional coordinate measuring equipment and other precision equipment or special machinery industry.

How to install linear bearings?

1. Before installing linear bearings, the raw edges, dirt and surface scars of the mechanical mounting surface must be removed. Linear bearings are coated with antirust oil. Please clean the datum surface with cleaning oil before installation. Usually, the datum surface is easy to rust after removing the antirust oil.

2. the linear bearing will be gently placed on the bed, the use of lateral fixing screws or other fixing fixture to make the line rail and the side mounting surface gently fit. Before installation and use, it is necessary to confirm whether the screw holes are consistent. Assuming that the machining holes of the base are not consistent and the bolts are forcibly locked, the combination accuracy and use quality will be greatly affected.

3. Tighten the positioning screw of the linear bearing in order from the center to both sides, so that the track is fitted with the vertical mounting surface, and stable accuracy can be obtained from the central position to both ends. After the vertical datum is tightened slightly, the locking force of the lateral datum is strengthened, so that the linear bearing can practically fit the lateral datum.

4. Use the torque wrench to lock the torque one by one according to various materials, and slowly tighten the positioning screw of the linear bearing slide rail.

5. Use the same installation method to install the auxiliary rail, and install the slide seat to the main rail and auxiliary rail individually. Note that after installing the linear slide on the slide seat, many accessories cannot be installed due to the limited installation space. The required accessories must be installed together at this stage.

6. Gently place the moving platform onto the sliding seat of the linear bearing main rail and auxiliary rail, and then lock the lateral pressing screw on the moving platform, which can be completed after installation and positioning.

Factory Appearance

The company was founded in 1998,covers an area of more than 90,000 square meters, plant area of more than 20,000 square meters, more than 200 employees, more than 20 technical engineers, has passed the international ISO9001:2008, ISO/ TS16949:2009 and other quality management system certification

Packing and shipping

For users to designdevelop, trial-produce all kinds of special purpose bearings, and do our best to provide high-end customers around theworld with the best solutions and good after-sales service!

Customer Visit

The company has many years of experience in the industrial field of bearing supporting and industrial service, the products are exported to the United States, Germany, Italy, France, the Czech Republic, Russia and other European and American countries and supporting enterprises, the company both at home and abroad enjoy a good business reputation!

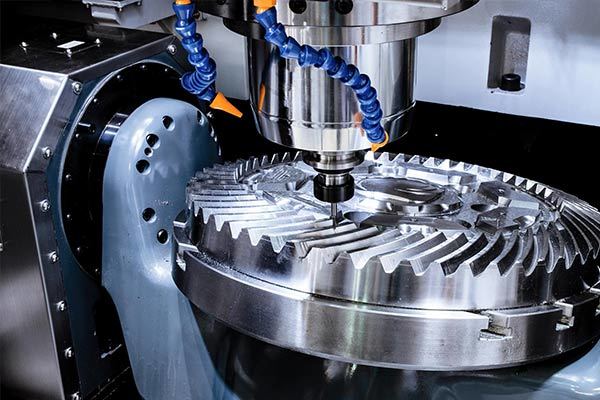

Application

Bearings are widely used in various industries for their excellent performance and reliability. They play a crucial role in ensuring smooth and efficient operations of various machinery and equipment.

RELATED PRODUCTS

MESSAGE