Electrically Insulated Bearing 6319M/C3VL0241 Deep Groove Ball Bearing

Keywords:

Category:

Deep Groove Ball Bearings

Product Details

Deep groove ball bearings are the most widely used bearing type and are particularly versatile. They have low friction and are optimized for low noise and low vibration which enables high rotational speeds.

Deep groove ball bearing consists of an outer ring, an inner ring, a set of steel balls and a set of cages.

It mainly bears pure radial loads, but also can bear joint loads. When it is subjected to pure radial load, its contact Angle is zero. When it has a larger radial game, that is, it has angular contact bearing performance, which can withstand a larger axial load. Deep groove ball bearing has small friction coefficient and high limit speed, so it has more advantages than thrust bearing when axial load is rotating at high speed. But because its aligning performance is limited, the concentricity of bearing installation should be high, otherwise it will affect the balance of its operation, increase the bearing stress, and thus shorten the working life.

Deep groove ball bearing simple structure, compared with other easy to achieve high precision, so can be mass production. In addition to the conventional models, it also has a variety of structural variations, such as deep groove ball bearing with dust cover, deep groove ball bearing with rubber ring and deep groove ball bearing with a stop groove and so on.

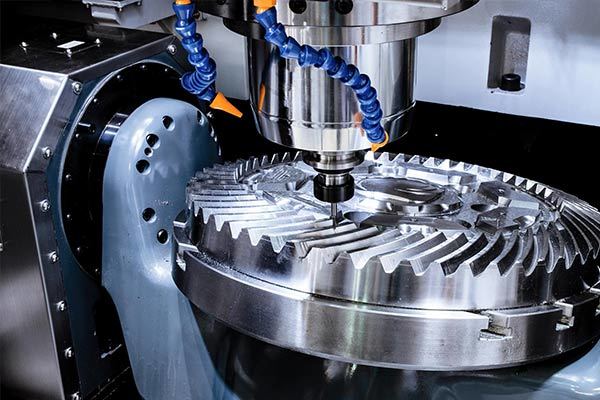

Main applications of deep groove ball bearing:

Transmission, instruments, electric machines, household appliances, internal combustion engines, traffic vehicles, agricultural machinery, construction machinery, construction machinery, roller skates, yo-yo, etc.

Working principle:

Deep groove ball bearings mainly bear radial load, but also can bear radial load and axial load. When it is only under radial load, the contact Angle is zero. When the deep groove ball bearing has a larger radial clearance, it has the performance of angular contact bearing and can withstand larger axial load. The friction coefficient of deep groove ball bearing is very small and the limit speed is very high.

Factory Appearance

The company was founded in 1998,covers an area of more than 90,000 square meters, plant area of more than 20,000 square meters, more than 200 employees, more than 20 technical engineers, has passed the international ISO9001:2008, ISO/ TS16949:2009 and other quality management system certification

Packing and shipping

For users to designdevelop, trial-produce all kinds of special purpose bearings, and do our best to provide high-end customers around theworld with the best solutions and good after-sales service!

Customer Visit

The company has many years of experience in the industrial field of bearing supporting and industrial service, the products are exported to the United States, Germany, Italy, France, the Czech Republic, Russia and other European and American countries and supporting enterprises, the company both at home and abroad enjoy a good business reputation!

Application

Bearings are widely used in various industries for their excellent performance and reliability. They play a crucial role in ensuring smooth and efficient operations of various machinery and equipment.

RELATED PRODUCTS

MESSAGE