22319CA Spherical Roller Bearing

Keywords:

Category:

Spherical Roller Bearing

Product Details

Bearing description:

The spherical roller bearing has a double row of rollers, with one common spherical raceway in the outer ring and two raceway in the inner ring and inclined at an Angle relative to the bearing axis. This ingenious structure makes it self-aligning, so it is not easy to be affected by the Angle of shaft and bearing box on the error or shaft bending, suitable for installation error or shaft deflection caused by Angle error. The bearing can bear radial load as well as bidirectional axial load.

The inner hole of the self-aligning roller bearing has two kinds: cylindrical and conical, and the taper of the conical cone hole is 1:30 and 1:12. This kind of conical inner hole bearing is equipped with a tight sleeve or a disconnecting sleeve, so that the self-aligning ball bearing with the conical inner hole can be conveniently and quickly assembled on the optical shaft or the stepped machine shaft.

Main uses:Paper making machinery, reducer, railway vehicle axle, rolling mill gearbox bearing seat, rolling mill roller, crusher, vibrating screen, printing machinery, woodworking machinery, all kinds of industrial reducer, vertical self-aligning bearing with seat.

Mainly cage:

Stamped steel reinforced cage (suffix E, very few in China).

Stamped steel plate cage (suffix CC), glass fiber reinforced polyamide 66 cage (suffix TVPB), machined brass two-piece cage (suffix MB).

Machined brass integral cage (suffix CA), stamping steel cage for vibration occasions (suffix JPA).

Brass cage for vibrating occasions (suffix EMA). The same structure, bearing on the code may be different.

Installation method:

The inner hole of the spherical roller bearing has two installation methods: cylindrical and conical, and the conical tapered hole is 1:12 and 1:30. By unloading the sleeve, the bearing can be installed on the optical shaft or stepped shaft conveniently and quickly. The cylindrical inner hole can also be installed on the tapered shaft with an inner taper sleeve.

Factory Appearance

The company was founded in 1998,covers an area of more than 90,000 square meters, plant area of more than 20,000 square meters, more than 200 employees, more than 20 technical engineers, has passed the international ISO9001:2008, ISO/ TS16949:2009 and other quality management system certification

Packing and shipping

For users to designdevelop, trial-produce all kinds of special purpose bearings, and do our best to provide high-end customers around theworld with the best solutions and good after-sales service!

Customer Visit

The company has many years of experience in the industrial field of bearing supporting and industrial service, the products are exported to the United States, Germany, Italy, France, the Czech Republic, Russia and other European and American countries and supporting enterprises, the company both at home and abroad enjoy a good business reputation!

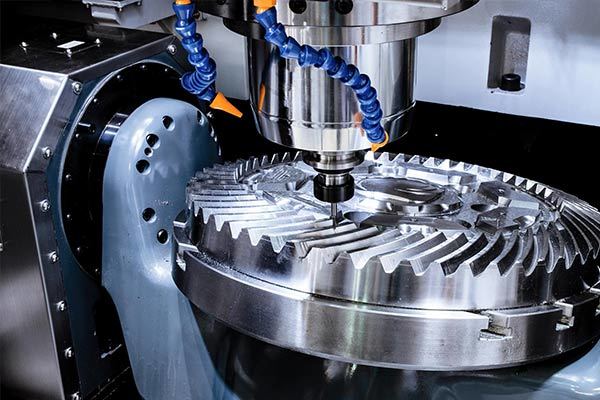

Application

Bearings are widely used in various industries for their excellent performance and reliability. They play a crucial role in ensuring smooth and efficient operations of various machinery and equipment.

RELATED PRODUCTS

MESSAGE