13685/21 Tapered Roller Bearing

Keywords:

Category:

Tapered Roller Bearings

Product Details

A single-row tapered bearing is usually adequate for the most straightforward applications (e.g., angular forces on a fixed point and with only mild fluctuation). To find the right one, you'll need to determine whether the end-use of the tapered bearing will have more radial or axial loads. There are axial-only tapered roller bearings called thrust tapered bearings that resemble flat rings or disks where the rollers are perpendicular to the bearing bore axis. When multiple bearings are required, it could be advantageous to use two- or more single-row tapered bearings rather than multi-row bearings within a single housing. One such example is if one bearing will need to be maintained, adjusted, or replaced separately from the other. Another is when there is a need to allow for flexibility in design and add or subtract individual single-row tapered bearings, which is impossible with a multi-row tapered bearing.

Structure:

This type of bearing is equipped with a round platform roller, the roller by the inner ring of the large rim.

Single row bearings can bear radial load and unidirectional axial load, and double row bearings can bear radial load and bidirectional axial load.Suitable for bearing heavy load and shock load.

According to the different contact Angle (α), it can be divided into three types: small cone Angle, middle cone Angle and large cone Angle. The larger the contact Angle is, the greater the axial load capacity is.

Outer ring and inner assembly (inner ring and roller and cage assembly) can be separated for easy assembly and disassembly.

Main applications of taper roller bearing:

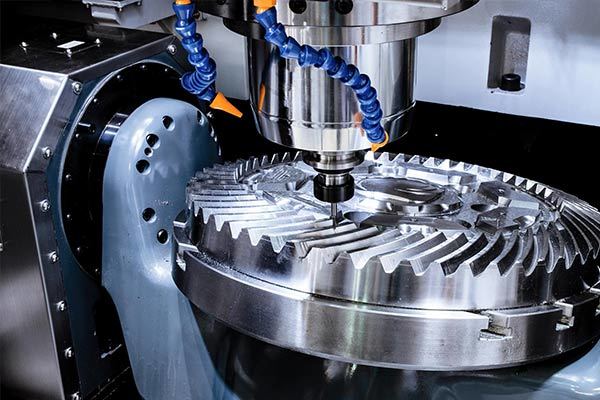

Front wheel, rear wheel, transmission, differential pinion shaft. Machine tool spindles, construction machinery, large agricultural machinery, railway vehicle gear reducer, rolling mill roller neck and reducer.

What is a taper roller bearing used for?

Tapered Roller Bearings are designed to reduce friction and, in turn, reduce the heat that can cause bearing structures to fail. This bearing is used in many industrial applications and is optimal for those undergoing excess loads.

Tapered roller bearings contain an inner ring, outer ring, and a number of tapered rollers. Looked at individually, the inner and outer bearing rings are also tapered, resembling a cone segment. Due to the large surface area contact, tapered roller bearings are able to withstand heavy axial and radial loads.

The most common material for ball bearing, roller bearing, and tapered roller bearing is chrome SAE 52100 bearing steel. This bearing can be made by high carbon content of 1.5% and has Rockwell hardness of about 64 HRC.

tapered roller bearings are typically used in gearboxes, hoisting equipment, rolling mills and machines in the mining industry. Four row tapered roller bearings are used almost exclusively in work roll applications such as rolling mills.

Factory Appearance

The company was founded in 1998,covers an area of more than 90,000 square meters, plant area of more than 20,000 square meters, more than 200 employees, more than 20 technical engineers, has passed the international ISO9001:2008, ISO/ TS16949:2009 and other quality management system certification

Packing and shipping

For users to designdevelop, trial-produce all kinds of special purpose bearings, and do our best to provide high-end customers around theworld with the best solutions and good after-sales service!

Customer Visit

The company has many years of experience in the industrial field of bearing supporting and industrial service, the products are exported to the United States, Germany, Italy, France, the Czech Republic, Russia and other European and American countries and supporting enterprises, the company both at home and abroad enjoy a good business reputation!

Application

Bearings are widely used in various industries for their excellent performance and reliability. They play a crucial role in ensuring smooth and efficient operations of various machinery and equipment.

RELATED PRODUCTS

MESSAGE