29748/10 Tapered Roller Bearing

Keywords:

Category:

Tapered Roller Bearings

Product Details

A single row tapered roller bearing has an outer ring, an inner ring and an inner ring assembly consisting of a set of tapered rollers enclosed by a basket cage.

The conical Angle of the outer ring raceway of a single row tapered roller bearing is between 10° and 19°, which can withstand the combined action of axial load and radial load at the same time. The larger the cone Angle, the greater the ability to bear axial load. Bearings with large tapered angles, rear code plus B, cone Angle between 25°~29°, it can bear large axial load. In addition, single-row tapered roller bearings can be adjusted during installation.

What types of loads can tapered roller bearings handle?

The angled and tapered shape of tapered roller bearings minimizes the stress caused by a combination of radial and axial loads. Radial and axial loads often combine to create different loads upon a bearing assembly. The ability to handle angular loads and changing angular loads – makes tapered roller bearings indispensable to various technical designs and industries. The tapered shape essentially concentrates radial and axial loads into a unified load that is more easily harnessed. Which angular loads can be harnessed depends on the precise angle of the tapered bearing. They can harness a comprehensive range of forces by configuring two or even more tapered bearings.

The steepness of the roller bearing's gradient increases the thrust/axial load it can handle, while a shallow angle increases the radial load capacity. As the radial load increases, the bearing experiences more stress against the sides of the bearing raceways. A more shallow angle minimizes stress, reducing pressure on the rollers. Increased axial load contributes to the stress applied to the top of the rollers. A steeper angle will distribute the pressure more towards the center of the bearing and less onto the rollers themselves.

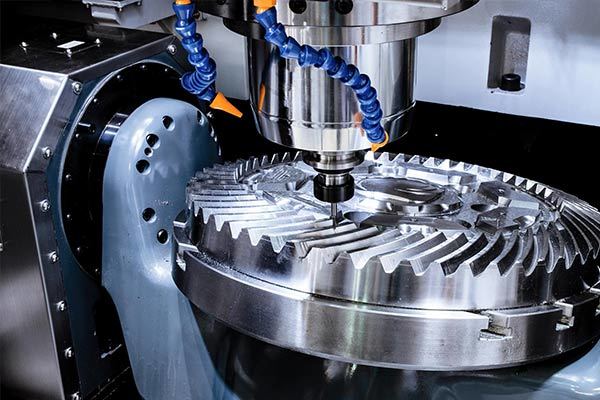

Common uses of tapered roller bearings

A tapered roller bearing is appropriate wherever a bearing must handle combination loads. One of the most common uses is maintaining axial balance, achieved with multiple tapered roller bearings along an axle or shaft. The tapered bearings will evenly distribute loads when adequately aligned, minimizing wear and tear on the components. With higher surface area, tapered roller bearings can distribute friction and heat from combination loads more efficiently than non-tapered rollers (which are more efficient than tapered bearings only with the most straightforward non-combination forces). This reduced friction increases the rotational speed of interfacing parts and makes tapered roller bearings ideal for use in:

- Engines

- Motors

- Gearboxes (especially those with helical gears)

- Wheels & axles

- Turbines & propellers

This equipment must combine many different angles and utilize them to drive motors, driveshafts, and other rotational components.

Factory Appearance

The company was founded in 1998,covers an area of more than 90,000 square meters, plant area of more than 20,000 square meters, more than 200 employees, more than 20 technical engineers, has passed the international ISO9001:2008, ISO/ TS16949:2009 and other quality management system certification

Packing and shipping

For users to designdevelop, trial-produce all kinds of special purpose bearings, and do our best to provide high-end customers around theworld with the best solutions and good after-sales service!

Customer Visit

The company has many years of experience in the industrial field of bearing supporting and industrial service, the products are exported to the United States, Germany, Italy, France, the Czech Republic, Russia and other European and American countries and supporting enterprises, the company both at home and abroad enjoy a good business reputation!

Application

Bearings are widely used in various industries for their excellent performance and reliability. They play a crucial role in ensuring smooth and efficient operations of various machinery and equipment.

RELATED PRODUCTS

MESSAGE