418/414 Tapered Roller Bearing

Keywords:

Category:

Tapered Roller Bearings

Product Details

Bearing Composition:

Tapered roller bearings are separated bearings, and the inner and outer rings of the bearings have tapered raceways. This kind of bearing is divided into single row, double row and four row tapered roller bearings and other different structural types according to the number of rows of rollers installed.

Single row tapered roller bearings can bear radial loads and single direction axial loads. When the bearing bears radial load, an axial component will be generated, so it needs another bearing that can bear the axial force in the opposite direction to balance it.

Characteristics of tapered roller bearings:

1. High speed, high precision

2.High rigidity, impact resistance, vibration resistance

3.Can bear large axial load

4.With high rolling contact fatigue strength

5.With high hardness and high mechanical strength, high wear resistance

6. High size performance

How to install tapered roller bearings?

Adjusting axial clearance For the installation of tapered roller bearing axial clearance can be adjusted by adjusting nuts on the journal, adjusting gaskets and threads in the bearing seat hole, or by pre-tightening springs and other methods. The size of axial clearance is related to the arrangement of bearing installation, the distance between bearings, the material of shaft and bearing seat, and can be determined according to working conditions.

For tapered roller bearings with high load and high speed, the influence of temperature rise on axial clearance must be considered when adjusting clearance, and the reduction of clearance caused by temperature rise must be estimated. That is to say, the axial clearance should be properly adjusted to a larger extent.

For bearings with low speed and bearing vibration, no-clearance installation should be adopted, or pre-load installation should be applied. The purpose is to make the tapered roller bearing roller and raceway have good contact, uniform load distribution, prevent the roller and raceway from vibration impact damage. After adjustment, the size of axial clearance is tested with a micrometer.

Factory Appearance

The company was founded in 1998,covers an area of more than 90,000 square meters, plant area of more than 20,000 square meters, more than 200 employees, more than 20 technical engineers, has passed the international ISO9001:2008, ISO/ TS16949:2009 and other quality management system certification

Packing and shipping

For users to designdevelop, trial-produce all kinds of special purpose bearings, and do our best to provide high-end customers around theworld with the best solutions and good after-sales service!

Customer Visit

The company has many years of experience in the industrial field of bearing supporting and industrial service, the products are exported to the United States, Germany, Italy, France, the Czech Republic, Russia and other European and American countries and supporting enterprises, the company both at home and abroad enjoy a good business reputation!

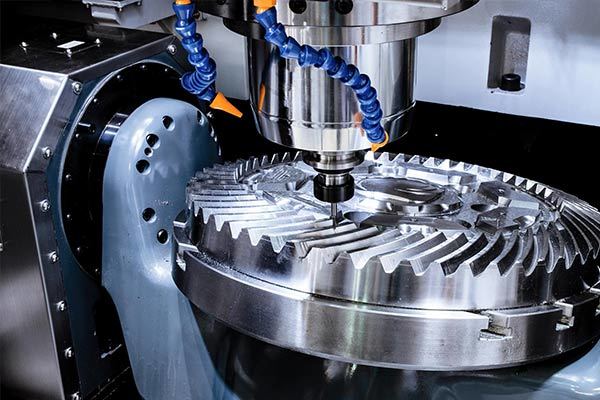

Application

Bearings are widely used in various industries for their excellent performance and reliability. They play a crucial role in ensuring smooth and efficient operations of various machinery and equipment.

RELATED PRODUCTS

MESSAGE